COURTESY :- vrindawan.in

Basic Of Preventive Maintenance And Troubleshooting

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure, and supporting utilities in industrial, business, and residential installations. Over time, this has come to include multiple wordings that describe various cost-effective practices to keep equipment operational; these activities occur either beforeor after a failure.

This chapter introduces preventive maintenance and the troubleshooting process. This chapter discusses troubleshooting as a concept. Detailed troubleshooting techniques are outlined

in subsequent chapters as they apply to specific software and devices.

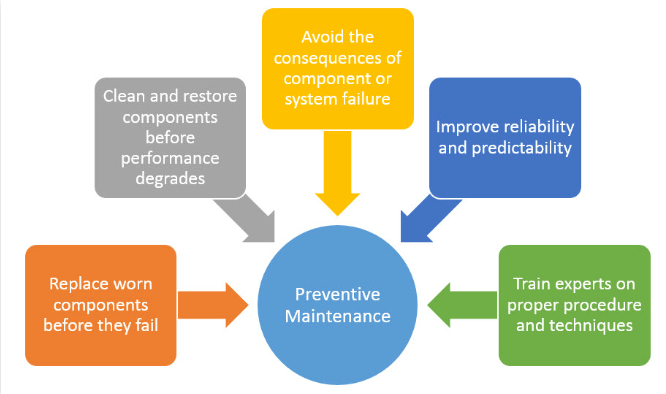

Preventive maintenance is a regular and systematic inspection, cleaning, and replacement

of worn parts, materials, and systems. Preventive maintenance helps to prevent failure of

parts, materials, and systems by ensuring that they are in good working order.

Troubleshooting is a systematic approach to locating the cause of a fault in a computer system. A good preventive maintenance program helps minimize failures. With fewer failures,

there is less troubleshooting to do, thus saving an organization time and money. Preventive

maintenance can also include upgrading certain hardware or software such as a hard drive

that is making noise, upgrading memory that is insufficient, or installing software updates

for security or reliability.

Preventive maintenance can be the key to keeping computer systems from experiencing serious problems, such as data loss and hardware failures, and it also helps systems have a longer life span. In this section, you study the need for preventive maintenance of a computer system. Following a good preventive maintenance plan can keep computer problems from being too troublesome.

Troubleshooting requires an organized and logical approach to problems with computers and other components. Sometimes issues arise during preventive maintenance. At other times, customers may contact you with problems. Taking a logical approach to troubleshooting allows you to eliminate variables and identify causes of problems in a systematic order. Asking the right questions, testing the right hardware, and examining the right data helps you understand the problem and form a proposed solution.

Troubleshooting is a skill that you refine over time. Each time you solve a problem, you increase your troubleshooting skills by gaining more experience. You learn how and when to combine steps, or skip steps, to reach a solution quickly. The troubleshooting process is a guideline that is modified to fit your needs.

This section presents an approach to problem solving that you can apply to both hardware and software.

The main goal behind PM is for the equipment to make it from one planned service to the next planned service without any failures caused by fatigue, neglect, or normal wear (preventable items), which Planned Maintenance and Condition Based Maintenance help to achieve by replacing worn components before they actually fail. Maintenance activities include partial or complete overhauls at specified periods, oil changes, lubrication, minor adjustments, and so on. In addition, workers can record equipment deterioration so they know to replace or repair worn parts before they cause system failure.

The New York Times gave an example of “machinery that is not lubricated on schedule” that functions “until a bearing burns out.” Preventive maintenance contracts are generally a fixed cost, whereas improper maintenance introduces a variable cost: replacement of major equipment.

Albeit chronologically much older, It is considered one section or practice inside the broader and newer predictive maintenance field, where new AI technologies and connectivity abilities are put to action and where the acronym CBM is more often used to describe ‘condition Based Monitoring’ rather than the maintenance itself. CBM maintenance is performed after one or more indicators show that equipment is going to fail or that equipment performance is deteriorating.

This concept is applicable to mission-critical systems that incorporate active redundancy and fault reporting. It is also applicable to non-mission critical systems that lack redundancy and fault reporting.

Condition-based maintenance was introduced to try to maintain the correct equipment at the right time. CBM is based on using real-time data to prioritize and optimize maintenance resources. Observing the state of the system is known as condition monitoring. Such a system will determine the equipment’s health, and act only when maintenance is actually necessary. Developments in recent years have allowed extensive instrumentation of equipment, and together with better tools for analyzing condition data, the maintenance personnel of today is more than ever able to decide what is the right time to perform maintenance on some piece of equipment. Ideally, condition-based maintenance will allow the maintenance personnel to do only the right things, minimizing spare parts cost, system downtime and time spent on maintenance.